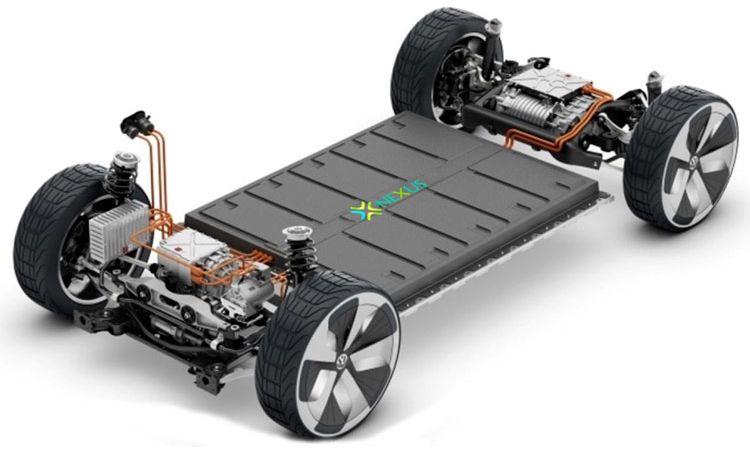

Toyota Motor has announced its plans to venture into the production of solid-state batteries for the next generation of electric vehicles (EVs). Solid-state batteries utilize thin layers of solid electrolytes to transport lithium ions between electrodes, in contrast to the liquid electrolytes used in conventional lithium-ion (Li-ion) batteries. While solid-state batteries have been successfully employed in small electronic devices, their implementation in mass-market electric vehicle production has been slower.

However, Toyota claims to have overcome durability issues associated with solid-state batteries, aiming to commence production by 2027-2028. This development is significant due to the numerous advantages solid-state batteries offer over conventional Li-ion batteries, including increased energy storage capacity, faster charging times, improved safety, and reduced range anxiety. Despite the challenges associated with manufacturing solid-state batteries, several major automakers and technology companies, such as Nissan, Honda, QuantumScape, Mercedes-Benz, Stellantis, TotalEnergies, Ford, BMW, and Hyundai, have invested in research and development efforts to bring this technology to the market.

Advantages of Solid-State Batteries

1. Enhanced Energy Storage and Range

Solid-state batteries are often referred to as the “grail” of battery development, as they can store more energy compared to liquid Li-ion batteries. This capability addresses a crucial consumer concern: range anxiety. According to a Reuters poll, 35% of Americans surveyed desired EVs with ranges of 500 miles or more, a distance currently offered by only a few models. By employing batteries with new technology, EVs can achieve extended driving ranges on a single charge, promoting the widespread adoption of electric mobility.

2. Reduced Charging Time

Another significant advantage of solid-state batteries is their potential to reduce charging time. Toyota anticipates that its solid-state battery will enable a charging time of 10 minutes or less, compared to the Tesla Supercharger network, which currently offers approximately 321 km of charge in 15 minutes. Faster charging times would significantly enhance the convenience of EV ownership, making electric vehicles more comparable to refueling a conventional combustion-engine vehicle.

3. Improved Safety

Solid-state batteries offer enhanced safety features compared to their liquid Li-ion counterparts. The volatile and flammable nature of the electrolyte in liquid Li-ion batteries presents risks of fire or chemical leaks, especially at high temperatures. Batteries with new technology, with their solid electrolytes, mitigate these safety concerns, providing a more secure and reliable energy storage solution for EVs.

4. Challenges in Manufacturing Solid-State Batteries

Despite the potential benefits, manufacturing solid-state batteries at scale poses several challenges. The primary hurdles include the design of stable, chemically inert solid electrolytes that can efficiently conduct ions between the electrodes. Additionally, solid-state batteries are currently more expensive to fabricate and are prone to cracking, resulting in higher costs compared to liquid Li-ion batteries. Toyota has not disclosed cost estimates for its solid-state battery EV or the required investment for ramping up production.

Major Players in Solid-State Battery Development

1. Toyota and Panasonic Partnership

Toyota has been actively driving solid-state battery development and has partnered with Panasonic on related projects. The collaboration aims to leverage Panasonic’s expertise in battery manufacturing to accelerate the commercialization of solid-state batteries.

2. Nissan’s Development Efforts

Nissan, the first automaker to launch a mass-market EV with the Leaf, has also prioritized the development of batteries with new technology. The company aims to achieve mass production by 2028, further contributing to the evolution of EV technology.

3. QuantumScape’s Contracts and Backing

QuantumScape, a US-based battery start-up backed by Bill Gates and Volkswagen, has secured contracts with six electric vehicle makers, including Volkswagen. QuantumScape’s solid

-state battery technology holds promise for future EVs, and collaborations with established automakers demonstrate their confidence in the company’s potential.

4. Automotive Cells Co and ProLogium Technology Partnership

Automotive Cells Co, a joint venture involving Mercedes-Benz, Stellantis, and Total Energies, has partnered with Taiwan-based battery maker ProLogium Technology to develop batteries with new technology. This collaboration signifies the commitment of leading automotive companies toward harnessing the potential of solid-state battery technology.

5. Solid Power’s Investments

US-based start-up Solid Power, in which Ford and BMW have made investments, is actively working on these prototype batteries. Hyundai Motor, another investor in Solid Power, has expressed its intention to commence mass production of solid-state batteries by 2030, signaling its long-term commitment to the technology.

Conclusion

The pursuit of solid-state batteries for the next generation of electric vehicles represents a significant advancement in battery technology. Toyota’s move toward production indicates progress in overcoming key challenges associated with durability and reliability. The advantages offered by solid-state batteries, such as increased energy storage, faster charging times, improved safety, and reduced range anxiety, have the potential to revolutionize the EV market. Major automakers and technology companies, including Nissan, QuantumScape, Mercedes-Benz, Stellantis, TotalEnergies, Ford, BMW, and Hyundai, are actively investing in research and development efforts to bring solid-state batteries to mass-market production. With ongoing advancements, solid-state batteries could accelerate the transition to electric mobility, making EVs more appealing to consumers and further driving the global shift toward sustainable transportation.